Today’s drills and taps manufacturing industry is well equipped with different flute grinding, clearance grinding and thread grinding machines. The most popular make of these machines are

Reishauer

Normac

Hartline

Guhring

Many of these machines are using hydrodynamic spindles for different applications. Needless to mention the ruggedness and accuracy of hydrodynamic spindles, it normally gives lot of trouble to refurbish after its first failure. It is just because the skill required maintaining radial clearances between bush bearings and shaft diameters, which very few maintenance crews possess.

Ultra Precision Spindles Pvt Ltd (UPSPL) has successfully manufactured spindles, which would replace these hydrodynamic spindles with antifriction bearing spindles. We have observed that these spindles run at relatively at low rpm but calls for high degree of radial and axial rigidity. We have used double row cylindrical roller bearings with taper bore and double row angular contact thrust bearings to achieve this rigidity factor.

UPSPL can offer you standard spindles, custom built spindle to meet your requirements. Apart from this we also have established state of art spindle room, which would cater requirements of reconditioning of spindles. Boneham & Turner is not a new name for engineering industry. We have set close association with this company and can get full support from them.

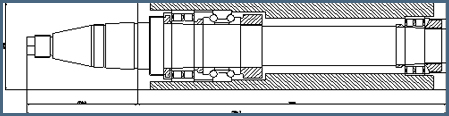

The schematic sketch of the spindle is shown below

The spindle has met all the quality parameters of end product and more over it would give maintenance friendliness while reconditioning the spindle keeping low downtime of the machine.

In case if you have any this kind of requirement, please contact

ULTRA PRECISION SPINDLES PVT LTD

S. No. 166, Pune Sinhagad Road, Nanded Phata,

Pune 411 041

Phone: 0091 20 24391881/ 2372/0444

Fax : 0091 20 24390700 / 1645

Cell : 09822454204 / 09822458694

Email : rajesh@svispm.com, pradeep@svispm.com